DH-A2 BGA Rework Station

Easy to operate.

Suitable for chips and motherboard of different sizes.

High successful rate of repairing.

شرح

DH-A2 BGA Rework Station

1.Application Of DH-A2 BGA Rework Station

Suitable for different PCB.

Motherboard of computer, smart phone, laptop, MacBook logic board, digital camera ,air conditioner, TV and

other electronic equipments from medical industry, communication industry, automobile industry, etc.

Suitable for different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP, PBGA,CPGA,

LED chip.

2.Product Features of DH-A2 BGA Rework Station

• Desoldering, mounting and soldering automatically.

• Characteristic of high volume (250 l/min), low pressure (0.22kg/ cm2), low temp (220°C) rework completely

guarantees BGA chips electricity and excellent soldering quality.

•Utilization of silent and low pressure type air blower permit the regulation of silent ventilator, the air flow can

be regulated to 250 l/Min the maximum.

•Hot air multi-hole round center support is especially useful for big-size PCB and BGA located in the center of

PCB. Avoid cold soldering and IC-drop situation.

•Temperature profile of bottom hot air heater can reach as high as 300°C, critical for big size motherboard.

Meanwhile, upper heater could be set as synchronized or independent work

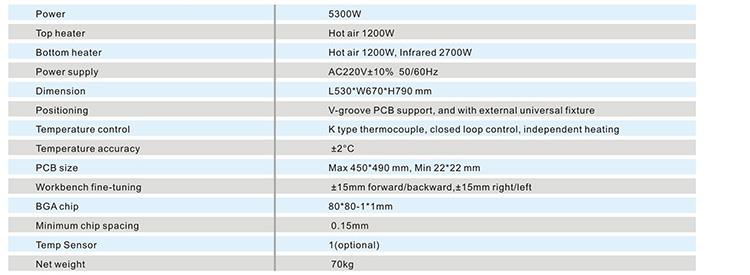

3.Specification of DH-A2 BGA Rework Station

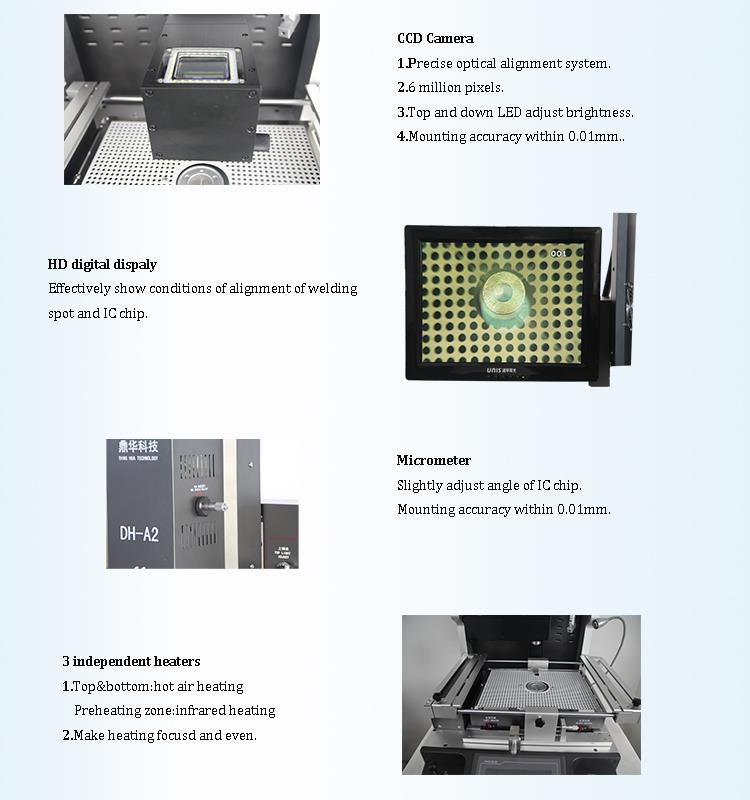

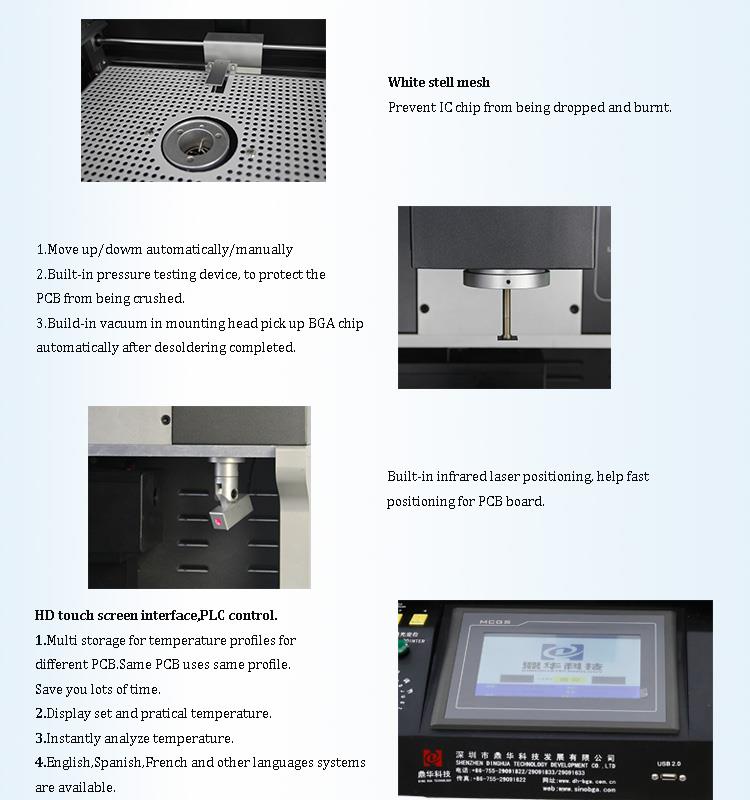

4.Details of DH-A2 BGA Rework Station

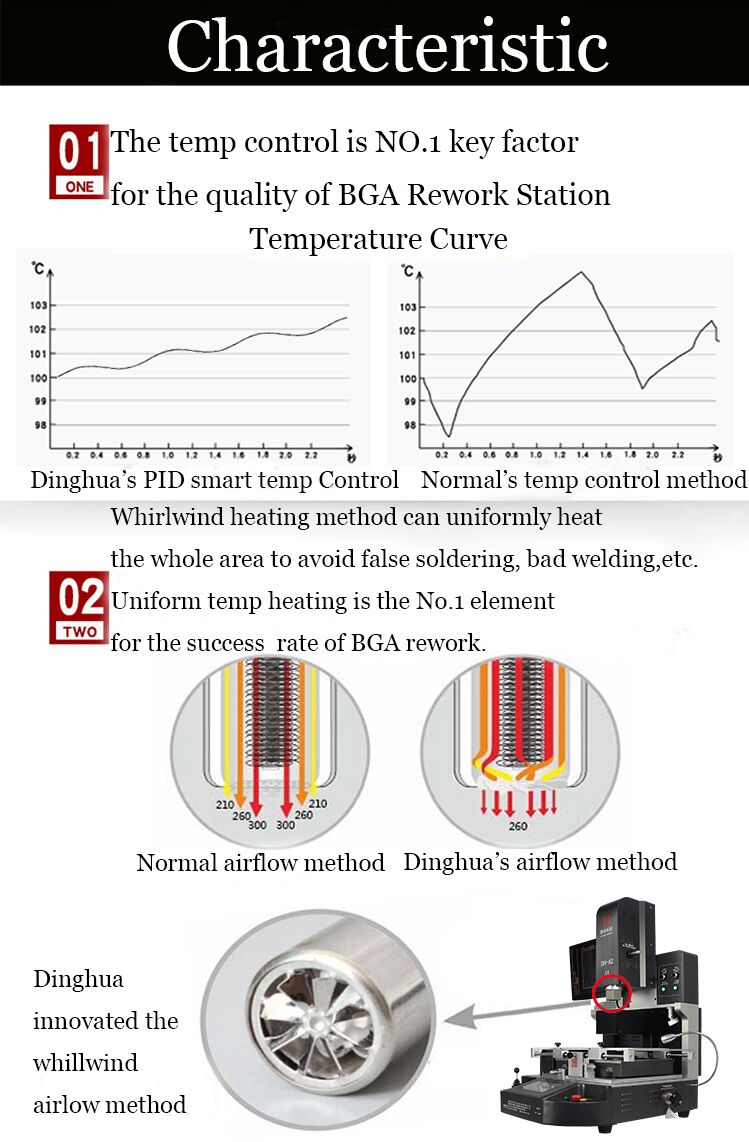

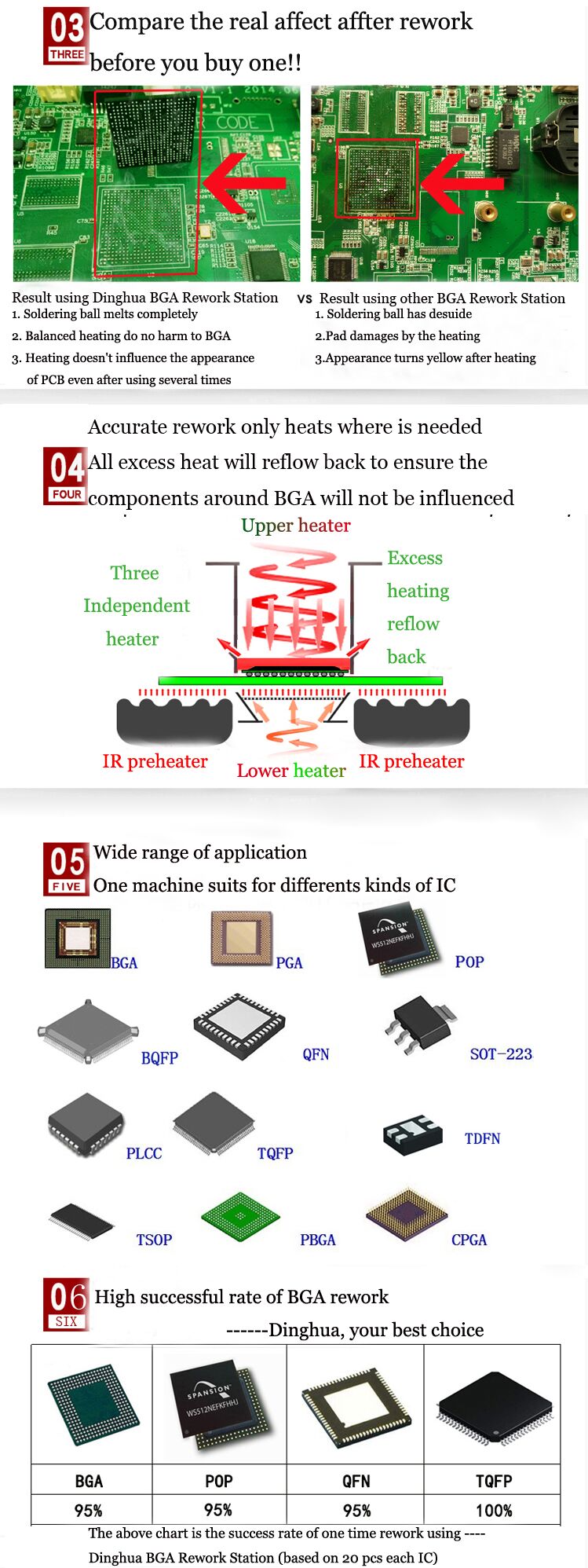

5.Why Choose Our DH-A2 BGA Rework Station?

6.Certificate of DH-A2 BGA Rework Station

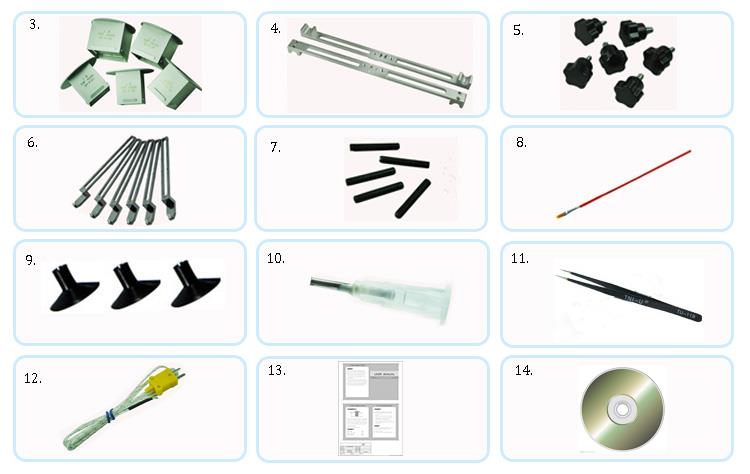

7.Packing & Shipment of DH-A2 BGA Rework Station

8.Related knowledge of DH-A2 BGA Rework Station

•What are BGA welding process technology principle?

The principle of reflow soldering used in BGA soldering. Here we introduce the reflow mechanism of solder balls during the soldering process.

When the solder ball is in a heated environment, the solder ball reflow is divided into three phases:

Preheating:

First, the solvent used to achieve the desired viscosity and screen printing properties begins to evaporate, and the temperature rise must be slow

(about 5 ° C per second) to limit boiling and splashing, to prevent the formation of small tin beads, and, for some components, to compare internal

stresses. Sensitive, if the outside temperature of the component rises too fast, it will cause breakage.

The flux (paste) is active, the chemical cleaning action begins, the water-soluble flux (paste) and the no-clean flux (paste) all have the same cleaning

action, except that the temperature is slightly different. Metal oxides and certain contaminants are removed from the metal and solder particles to

be bonded. Good metallurgical solder joints require a "clean" surface.

As the temperature continues to rise, the solder particles first melt separately and begin the "lighting" process of liquefaction and surface suction.

This covers all possible surfaces and begins to form solder joints.

Reflux:

This stage is of the utmost importance. When a single solder particle is completely melted, it combines to form a liquid tin. At this time, surface tension

begins to form the surface of the solder fillet if the gap between the component leads and the PCB pad exceeds 4 mils (1 mil = one thousandth One inch),

it is very likely that the pin and the pad are separated due to surface tension, which causes the tin point to open.

Cool down:

During the cooling phase, if the cooling is fast, the tin point strength will be slightly larger, but it should not be too fast to cause temperature stress inside

the component.